Behind The Still: Rochester Style Bourbon

Behind The Still: Rochester Style Bourbon

ROCHESTER BUSINESS JOURNAL

Written by Thomas Adams

September 27, 2013

Making great bourbon is a complex and nuanced art and we’re diving deeper into how our bourbon making process differs from other distillers. Black Button’s unique distillation process and geographic terroir create a style unto itself. Literally, nobody in the whole world makes bourbon the way Black Button does, simply because they can’t! It’s a combination of our equipment, process, ingredients, and climate that defines the special Rochester Style of Black Button Bourbon. So, let’s jump in and see what sets our bourbon apart.

UNIQUE EQUIPMENT: COLUMN TO POT TO COLUMN STILL

Distilling bourbon involves a complex network of vessels, pipes and valves with a Still as the primary piece of equipment. Most distilleries have either a pot or column stills. Pot stills make small batches of spirits that are cold in the morning, heat up through out the day and cool again the next night. Column stills are more efficient and run continuously. While they produce higher volumes, it’s harder to control the variables of the run. They do however make cleaner whiskey which is sometimes good, but can detract from flavor development. Black Button Distilling’s equipment was custom designed by our Master Distiller Jason Barrett. It was then heavily modified by our distilling team to increase flavor while maintaining the purity of the whiskey. We call this a Column to Pot to Column system.

UNIQUE PROCESS: DOUBLE PASS DISTILLATION

What distillers do with this equipment is as important as the equipment itself. At Black Button, we use a process called Double Pass Distillation. This process includes heating up the whiskey and running it through a still to collect the vapor as it condenses back into a liquid (also known as a distillate). This distillation process is then done twice.

You’ll see this process used in Scotch and Irish Whiskey distilling. It was also used in American Whiskey along the frontier 100 years ago. Here in Rochester at Black Button Distilling, we still practice Double Pass Distillation, but with a twist. Our unique Column to Pot to Column system allows for the purity and efficiencies of a column to remove the beginning (aka “heads”) and end (aka “tails”) of a run – but keep the middle (or “Hearts”) which are full of flavor and complexity. This process is unique to us, and we think it makes for the most flavorful whiskey around.

SUPPLIER INGREDIENTS

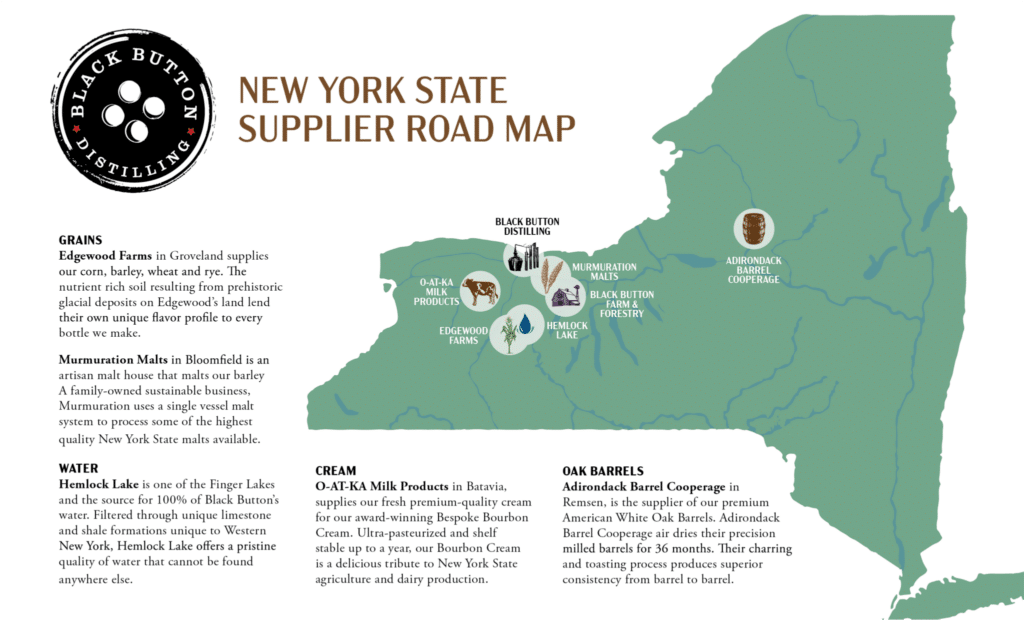

The ingredients we use are another unique factor that contributes to the making of bourbon – Rochester Style. As a licensed Farm Distillery, 100% of Black Button’s whiskey ingredients are sourced from within 50 miles of the distillery to make our bourbon.

Meet our Ingredient Sources:

Edgewood Farms in Groveland, NY is 48 miles south of Black Button in the famous Finger lakes Region – an area known for its nutrient rich soil resulting from prehistoric glacial deposits. The grains grown by Edgewood lend their own unique flavor profile to every barrel of Black Button Bourbon. There are places on the Edgewood’s farm where the topsoil is over 400 feet deep, and the nutrients are so rich that they can grow heirloom varieties of grains including the Danko Rye we use to craft our Empire Rye Whiskey.

Hemlock Lake is one of the Finger Lakes and is 36 miles away from the distillery and the source for 100% of Black Button’s water. Filtered through limestone and shale formations specific to Western New York, Hemlock Lake offers a pristine quality of water that cannot be found anywhere else

Murmuration Malts is 25 miles from Black Button in Bloomfield NY. Murmuration Malt is an artisanal malt house that malts the barley used in Black Button Bourbon. A family-owned sustainable business, Murmuration uses a single vessel malt system to process some of the highest quality New York State malts available. Better malt means that we get more sugar conversion from the corn, wheat, and rye as well as a depth of flavor not seen in mass produced grains.

Adirondack Barrel Cooperage in Remsen is just outside of New York’s Adirondack State Park. The supplier of our premium American White Oak Barrels, Adirondack Barrel Cooperage air dries their precision milled barrels for 36 months. Their charring and toasting process produces consistent toast and char levels from barrel to barrel which were hand chosen by our master distillers after dozens of trials.

WESTERN NEW YORK’S ENVIRONMENT & CLIMATE

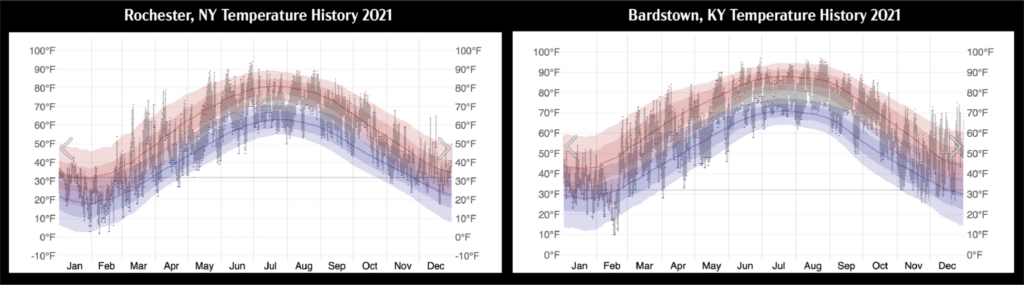

Finally, when it comes to making our one-of-a-kind bourbon, weather plays an important role. Annual temperature fluctuation impacts our bourbon’s aging process in a way that cannot be replicated in the more temperate southern regions. Weather patterns impacted by the Great Lakes of Erie and Ontario as well as Western New York’s latitude means our bourbon experiences the changing of the seasons. Both the deep cold of Winter and heat of Summer favorably impact the barrel aging process of our bourbon. Temperatures in Rochester can swing as much as 30°F in a single day and as much as 110°F throughout the year. With temperature fluctuations of 20°F or more, the staves of each barrel expand, and contract more than barrels do in more famous whiskey producing areas like Kentucky or Scotland.

A comparison of Rochester and Bardstown, Kentucky annual temperatures illustrates this. While Rochester experiences summer high temperatures nearly as high as Bardstown does, Rochester summer low temperatures are much lower than they are in Kentucky. And as any Western New Yorker can attest, Rochester winters get very cold … much colder than in Kentucky. This extreme variance in temperature allows for quicker evaporation of naturally occuring volatile compounds. It also allows the bourbon deeper exposure to the caramelization layer of the charred oak, shortening the time the bourbon needs to age.

ROCHESTER STYLE BOURBON … STRAIGHT FROM NEW YORK

We hope you’ve enjoyed learning how we make our bourbon whiskey at Black Button Distilling. Please join us in raising a glass and enjoying the essence of Rochester Style Bourbon … Straight from New York! Our fine spirits are available online for curbside pick up at our Rochester Tasting Room or for delivery throughout the U.S. where permitted by state regulations.